Personal Protective Equipment (PPE) is crucial for protecting workers against occupational hazards. These equipments are specially designed to protect body parts from potential workplace accidents and occupational diseases. To ensure a secure work environment, it is important to have good management of your PPE. Small equipment includes tools and generally equipment of insignificant value. KEEP CONTROL offers an innovative solution to simplify the inventory of PPE and these equipments and to limit loss and theft through a unique identifier associated with each piece of equipment, with NFC tagging or direct recognition of it using your smartphone’s camera.

Optimizing the Traceability of PPE and Small Equipment

Employers are responsible for providing PPE to their employees when the work environment presents a risk to their health and safety. When company activities lead employees to work on construction sites or outside of the company, the PPE and equipment provided by the employer are exposed to loss or theft. Therefore, it is essential to ensure the identification and tracking of these safety equipments and small tools under the employer’s responsibility. Simplifying inventories is necessary for good management.

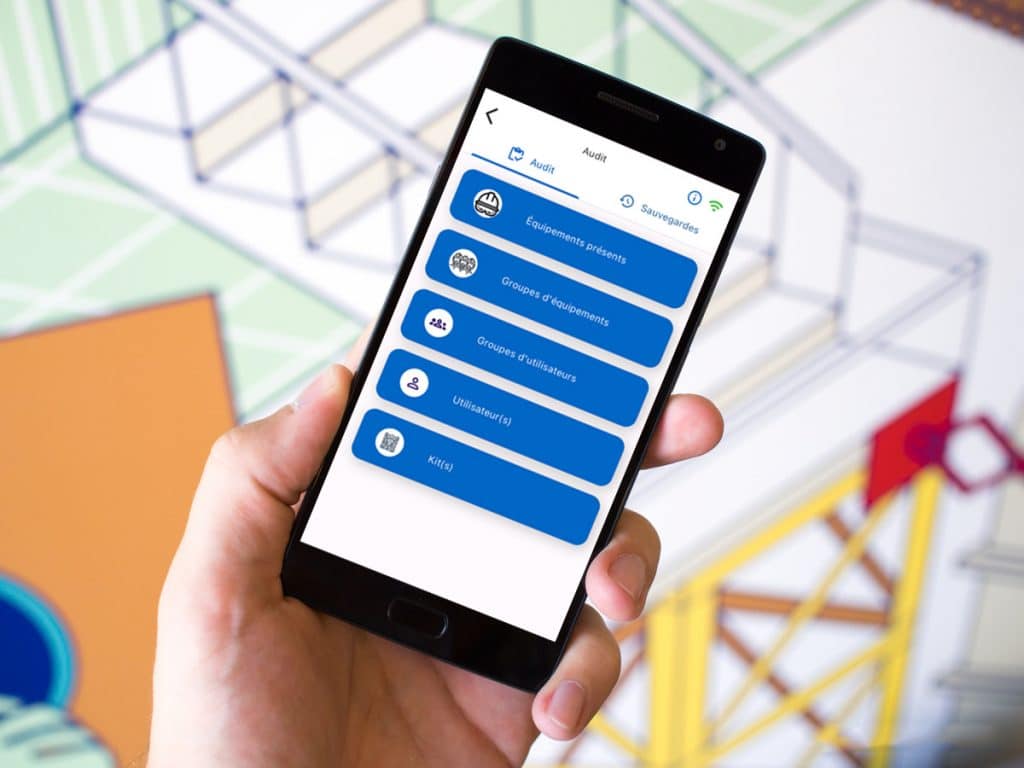

Thanks to our innovative solution, KEEP CONTROL allows you to manage each equipment, its compliance, and its assignments to personnel and the company’s stock. The unique identification of each piece of equipment in our software through our NFC tagging gives access to information and documents, to the product’s life record. The traceability of all your equipments and materials is then possible remotely.

In our KEEP CONTROL software, you will find a life record for each piece of equipment including :

- The type of equipment;

- The brand;

- The model;

- The serial number;

- Your internal identifier;

- The date of the next check;

- The expiration date;

- The date of the last assignment;

- The location of the assignment;

- The list of maintenance/repairs carried out;

- All documents/videos attached to this equipment.

Ensuring Periodic Verification of PPE, Calibration, or Calibration of Equipment

To simplify your inventory of PPE and small equipment, periodic verification, calibration, or calibration are points not to be overlooked. Periodic verifications of PPE allow for checking their condition and ensuring their performance. This includes, for example, scratches or impact marks on bump helmets, or worn seams on fall protection harnesses, or malfunctioning clasps on carabiners. These checks for equipment correspond to, for example, the calibration of welding stations, the calibration of gas or network detectors. Proper tracking of this equipment ensures the quality and performance of the company’s work.

With its software, KEEP CONTROL enables you to record all movements and events during the lifecycle of the equipments via the mobile application by operators in the field. No more unnecessary alerts for misplaced or stolen equipment. KEEP CONTROL offers a modern solution for consulting compliance and control reports. If equipment is missing at the end of a project, you can easily identify what is missing. You can remotely manage equipment allocations and flows from your stocks and track user allocations in real-time.

The benefits of good Personal Protective Equipment management

Benefits of Good Management of Personal Protective Equipment Good management of your PPE, regulated equipment, and other materials offers several benefits :

- Time savings;

- Cost optimization;

- A secure environment and thus less risk of accidents;

- Better control over the quality of work performed;

- Tracking of maintenance, and compliance of equipment;

- Management of all non-conformities for your certifications.

Simplify your inventory of PPE and equipment under control, with the recording of all events thanks to KEEP CONTROL. Each equipment reading integrates into the inventory, which allows focusing on the equipment and materials that have not been read in the mobile application. Unread equipment can be declared lost to avoid being cluttered by control alerts in your mailbox!

Rigorous tracking of an equipment park allows anticipating non-conformities because, from experience, it is known that equipment not compliant at the time of control could have been subject to a claim without waiting for the annual control. So, contact us to learn more! Our team will be delighted to show you all the advantages of our solution.